The primary differences between conventional heaters (like space heaters or water heaters) and induction heating systems lie in their heating mechanisms, efficiency, application versatility, and safety features:

1.Heating Mechanism:

1).Conventional Heaters: These typically operate on principles such as convection (air heating), conduction (direct contact heating), or radiation (infrared heaters). They may use electric resistance elements or combustion of fuels like natural gas or propane.

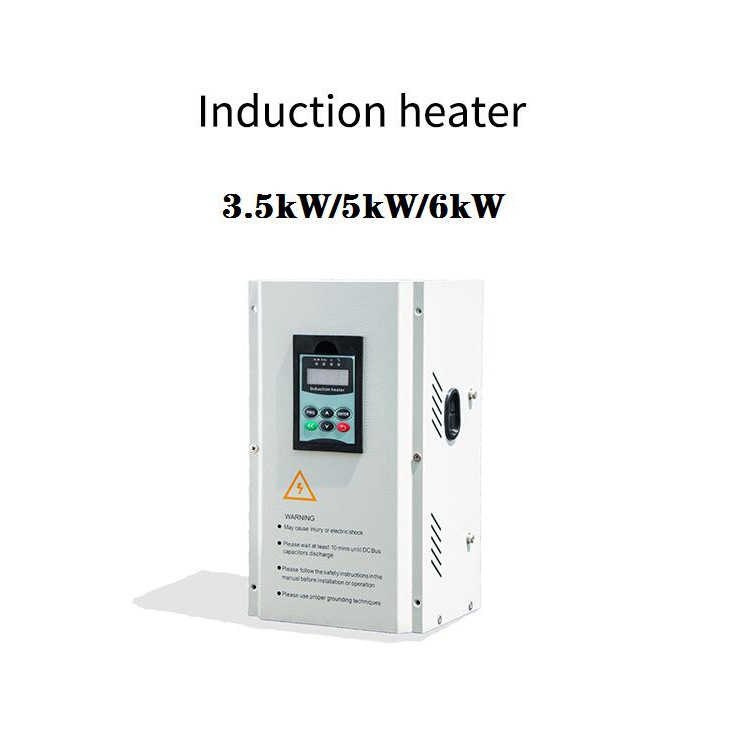

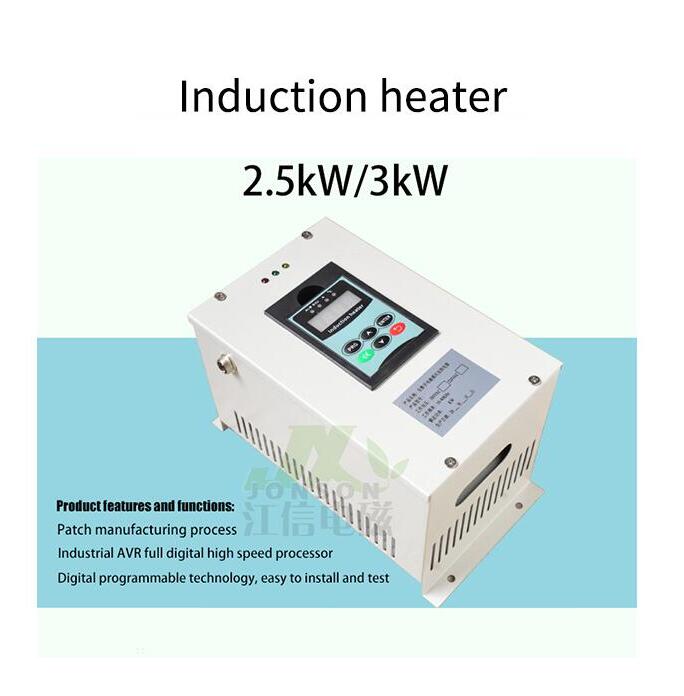

2).Induction Heating: This method employs electromagnetic fields to directly heat metal or other conductive materials. An alternating current passes through a coil, generating a dynamic magnetic field that induces eddy currents and heat within the conductive object itself.

2.Efficiency:

1).Conventional Heaters: The efficiency varies by type. Radiant heaters can be very efficient at directing heat to specific zones without heating unnecessary spaces. However, convection heaters can lose a lot of heat through the ducts or in open areas.

2).Induction Heating: Offers very high efficiency as it directly heats the object with minimal heat loss to the environment. This results in faster heating times and lower energy use, especially beneficial in industrial processes.

3.Application Versatility:

1).Conventional Heaters: They are versatile in their usage, suitable for residential, commercial, and some industrial settings for space heating, water heating, and more.

2).Induction Heating: Primarily used in industrial applications and cooking (induction cooktops). It excels in processes requiring precise, controlled, and quick heating such as in metalworking, manufacturing, and culinary arts.

4.Safety:

1).Conventional Heaters: Safety concerns may include fire risks from overheated elements, burns from direct contact, and potential hazards from gas leaks in combustion-based heaters.

2).Induction Heating: Considered safer as the heat is generated within the object itself, meaning the device (like an induction cooktop) remains cool to the touch. This reduces burn and fire hazards significantly.

5.Speed:

Conventional Heaters: Generally slower as they need to heat up their own elements and then transfer this heat to the air or direct surroundings, which can take considerable time.

15.Induction Heating: Offers very rapid heating capabilities because it generates heat directly within the material, making it highly efficient for processes like melting, soldering, or cooking.

6.Cost:

1).Conventional Heaters: Usually less expensive upfront compared to induction systems, both in terms of purchase price and installation costs.

2).Induction Heating: Typically has higher initial costs, particularly for industrial-grade equipment, but can be more cost-effective over time due to lower operating costs and higher efficiency.

Overall, induction heating is a specialized technique that excels in applications requiring quick, efficient, and precisely controlled heating, whereas conventional heaters are more generalized and suitable for a wide range of everyday heating tasks.