Induction heating exhaust gas treatment equipment is an advanced technology designed for treating industrial exhaust gases through the principles of electromagnetic induction. This type of equipment is especially useful in scenarios where exhaust gases need to be processed through thermal decomposition, catalytic reactions, or other heat-related processes. Below, I’ll provide a detailed introduction to the components, operating principles, and applications of this equipment.

Components

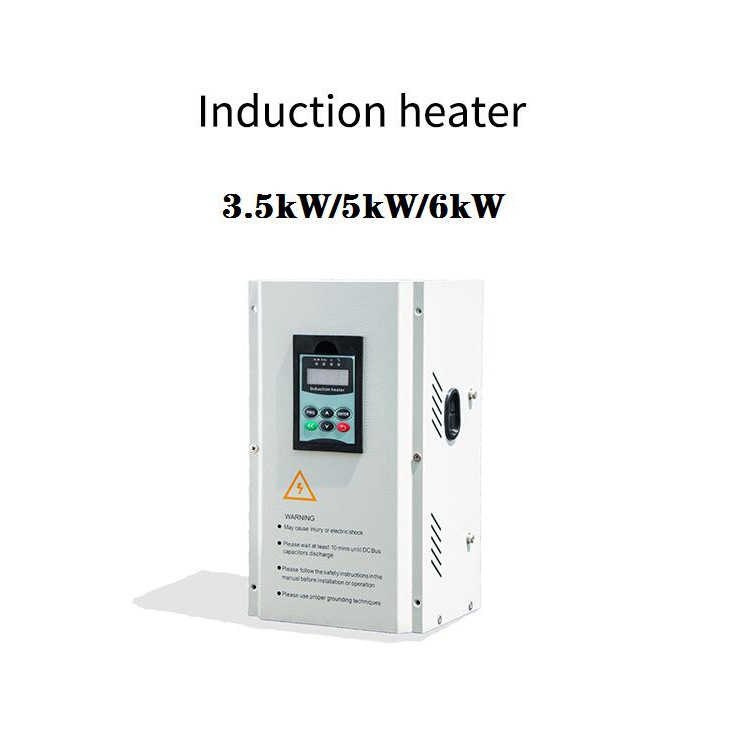

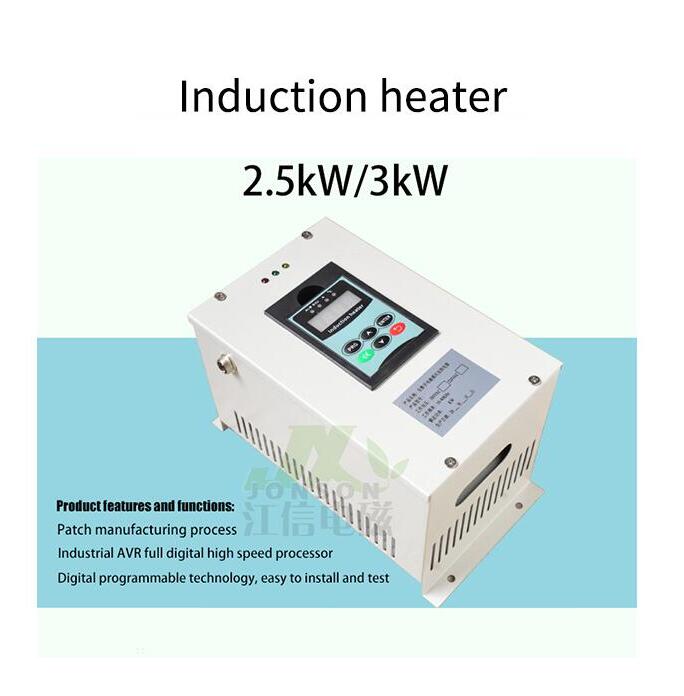

1.Induction Heating Unit: This is the core component, typically consisting of a high-frequency power source and an electromagnetic coil. The coil generates a high-frequency magnetic field used to heat the passing exhaust gases.

2.Reaction Chamber: Here, the heated gases undergo chemical reactions. This chamber is usually lined with high-temperature-resistant materials and may include catalysts.

3.Control System: Regulates the power output, monitors temperatures, and oversees the process. It generally includes temperature sensors, pressure sensors, and flow meters.

4.Gas Inlet and Outlet System: Includes ducts for the intake and exhaust of gases, ensuring efficient entry and exit from the reaction chamber.

Operating Principle

The operating principle of induction heating exhaust gas treatment equipment is based on electromagnetic induction heating. An electromagnetic coil produces a changing magnetic field, inducing eddy currents in conductive materials within the gas stream (or in particles suspended in the gas). These eddy currents generate heat through internal friction and collisions, converting electrical energy into thermal energy. This method of heating is rapid, uniform, and allows for precise temperature control.

Applications

5.Volatile Organic Compound (VOC) Removal: Effective in settings like paint shops, printing, and chemical production where VOCs are emitted.

6.Pyrolysis and Gasification: Treats carbon-containing gases, transforming them through high-temperature processes into simpler compounds or usable energy.

7.Medical Waste Treatment: High-temperature sterilization and decomposition of medical waste gases.

8.Catalytic Purification of Industrial Exhaust: High temperatures enhance the activity of catalysts, improving the efficiency of pollutant removal from exhaust gases.

Advantages

9.High Energy Efficiency: The energy conversion efficiency of induction heating is high, significantly reducing energy consumption.

10.Environmentally Friendly: Generates no secondary pollutants, offering a cleaner alternative to traditional combustion methods.

11.Rapid Response: Heats quickly to the required temperatures, enhancing process efficiency.

12.Ease of Operation: Automated control systems make operation and maintenance relatively simple.

Conclusion

Induction heating exhaust gas treatment equipment offers an efficient and environmentally friendly solution for handling industrial exhaust gases, particularly where rapid and high-temperature processing is required. It meets the strict demands of modern industry for environmental protection and energy efficiency, making it a strong candidate for future exhaust gas treatment technologies.