The application advantages of induction heating extruder equipment are manifold and can be summarized as follows:

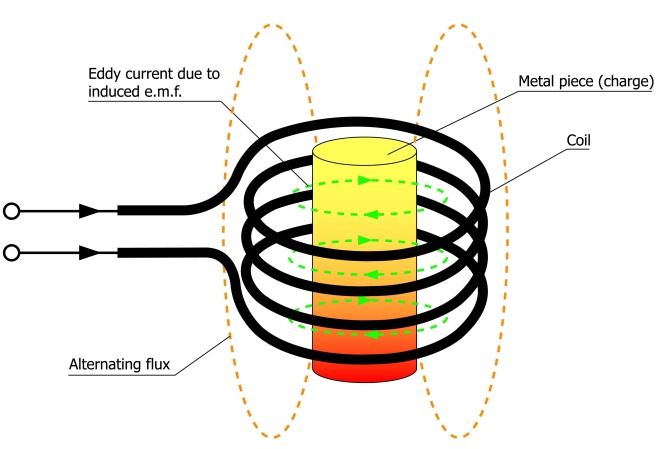

1.Efficiency: Induction heating extruder equipment is highly efficient in heating materials, particularly metals, due to the direct conversion of electrical energy into heat. This efficiency leads to reduced energy consumption and lower operating costs compared to conventional heating methods.

2.Precision Heating: Induction heating allows for precise and localized heating of materials, enabling better control over the temperature profile during the extrusion process. This precision helps in achieving consistent product quality and desired material properties.

3.Rapid Heating: Induction heating provides rapid heating rates, significantly reducing heating times compared to traditional heating methods. This capability contributes to increased production throughput and shorter cycle times in extrusion processes.

4.Clean and Environmentally Friendly: Induction heating extruder equipment produces no emissions or pollutants during operation, contributing to a cleaner working environment and reduced environmental impact. It eliminates the need for fossil fuels or other combustion sources, resulting in cleaner and greener manufacturing processes.

5.Versatility: Induction heating can be applied to a wide range of materials, including metals and non-metals, making it suitable for various extrusion applications. Whether it's plastic extrusion, metal extrusion, or composite materials, induction heating extruders offer versatility in heating different types of materials effectively.

6.Uniform Heating: Induction heating provides uniform heating across the entire cross-section of the material being processed, ensuring consistent material properties and product quality. This uniformity minimizes material waste and enhances the overall efficiency of the extrusion process.

7.Temperature Control: Induction heating extruder equipment often incorporates advanced temperature control systems, allowing precise adjustment and monitoring of the heating process. This ensures that the material is heated to the desired temperature range, optimizing the extrusion process and product performance.

In summary, induction heating extruder equipment offers numerous advantages, including high efficiency, precision heating, rapid heating rates, environmental friendliness, versatility, uniform heating, and precise temperature control. These advantages make it a preferred choice for various extrusion applications across industries.