The application scenarios of induction heating power supply are diverse and span various industries due to the versatility and efficiency of induction heating technology. Here are some common application scenarios:

1.Metallurgy and Metalworking Industries:

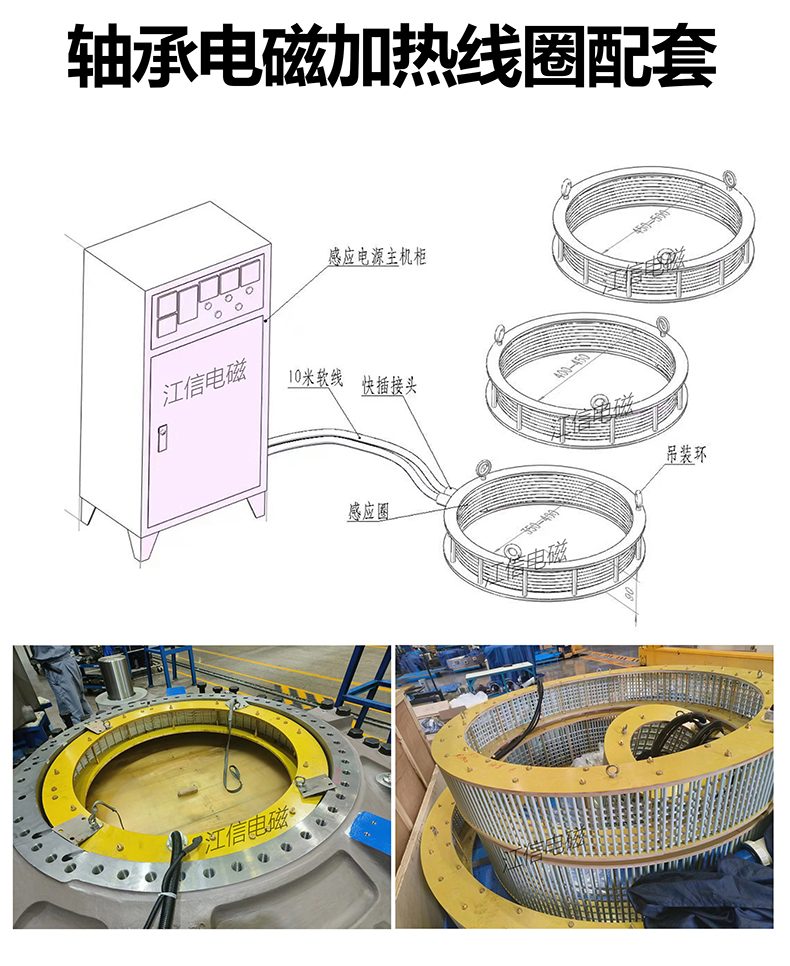

2.Hardening: Induction heating power supplies are widely used for surface hardening of metal components, such as gears, shafts, and bearings, to increase their wear resistance and durability.

3.Annealing: In metalworking processes, induction heating is employed for annealing operations to relieve internal stresses, improve ductility, and enhance machinability of metals.

4.Brazing and Soldering: Induction heating is utilized for brazing and soldering applications, where precise and localized heating is required to join metal components effectively.

5.Automotive Industry:

6.Heat Treatment: Induction heating power supplies play a crucial role in heat treatment processes in the automotive sector, including induction hardening of crankshafts, camshafts, and other critical components.

7.Welding Preheating: Induction heating is used for preheating components before welding to reduce thermal stresses, ensure proper fusion, and improve weld quality.

8.Aerospace and Aviation:

9.Surface Modification: Induction heating technology is employed for surface modification techniques like case hardening and shot peening to improve the fatigue resistance and performance of aerospace components.

10.Joining Processes: Induction heating is utilized for joining dissimilar materials in aircraft assembly, such as bonding titanium alloys or composite materials.

11.Electronics Manufacturing:

12.Soldering and Desoldering: Induction heating power supplies are used for soldering and desoldering electronic components on circuit boards, ensuring precise and controlled heating without damaging sensitive parts.

13.Component Manufacturing: Induction heating is utilized for processes like thermal bonding, sealing, and encapsulation of electronic components.

14.Plastics Industry:

15.Injection Molding: Induction heating power supplies are employed for heating molds in injection molding processes, enhancing the flow characteristics of molten plastic and improving production efficiency.

16.Thermoforming: In thermoforming operations, induction heating is used to heat plastic sheets or films, enabling them to be shaped into desired forms.

17.Food Industry:

18.Sealing and Packaging: Induction heating technology is utilized for sealing containers and packaging materials in the food industry, ensuring product integrity and extending shelf life.

These are just a few examples of the diverse application scenarios of induction heating power supplies across various industries. The technology's flexibility, efficiency, and precision make it suitable for a wide range of heating and material processing applications.